As I keep visiting different watchmakers in Switzerland over the past 7 years, I am learning more and more about true watchmaking, about the old skills which are becoming increasingly rare while industrialization is eliminating a lot of the old skills such as emaileur and guillocheur, finisseur and other manual skills and skills how to use old machines which are not electric and industrial.

Yes, you can make pinions and wheels look perfect by electrolytic methods, but honestly, nothing beats the work skilled hands can accomplish.

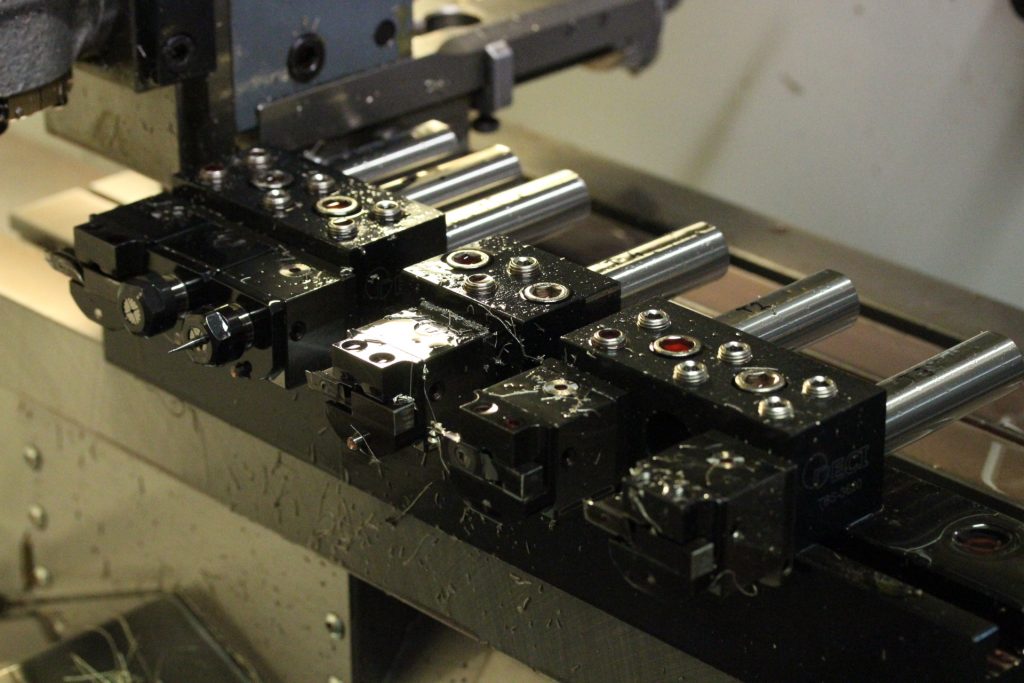

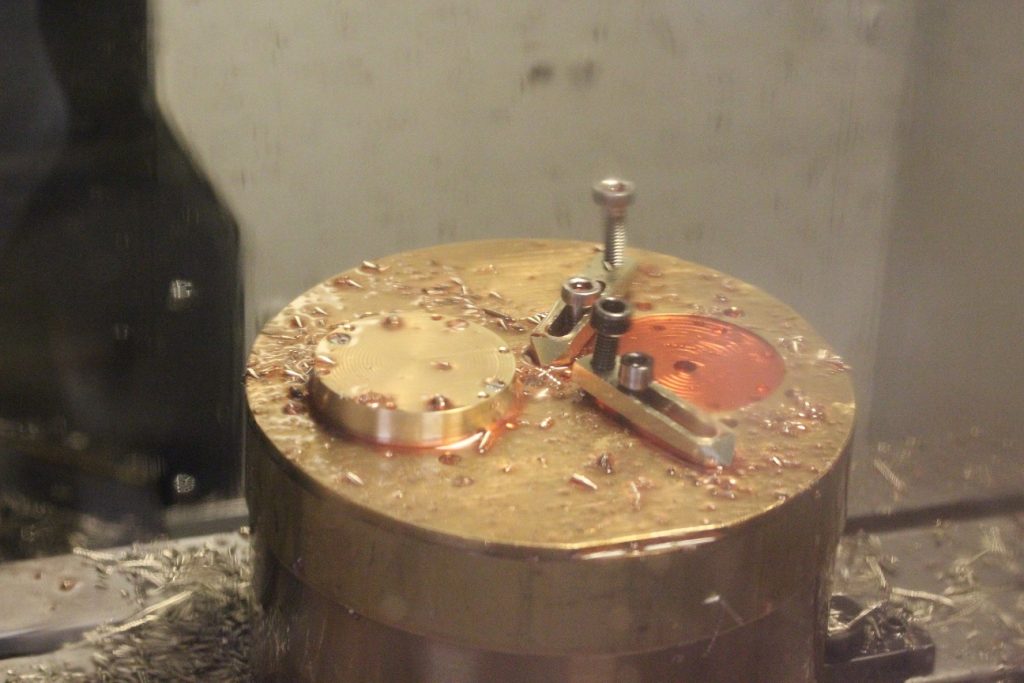

The mess you see in the picture above is what is left from a cutting tool used to create small watchmovement parts.

The mess you see in the picture above is what is left from a cutting tool used to create small watchmovement parts.

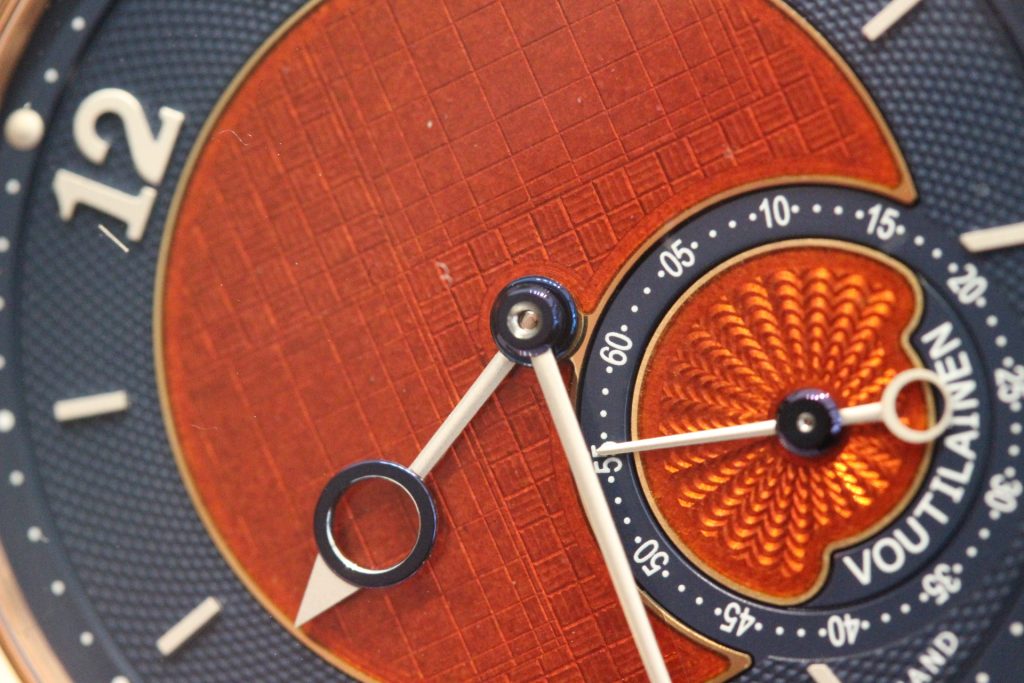

Having met Kari Voutilainen for the first time at SalonQP in London, I got to see his timepieces which are of a whole other world, made by hand, made the way watches once used to be made before industrialization and modern machinery took the jobs from highly skilled watchmakers and artisans.

Kari only made 38 watches last year, and he told me in confidence that he is probably going to make even less. Not because he is suffering from a lack of demand, but because he wants to keep up his level of quality which if not unique has to be at least extremely rare in today’s watchmaking in Switzerland or anywhere else for that matter.

Most of Kari Voutilainen’s watches are unique pieces, however, he sometimes makes limited editions with a few pieces, generally not more than 10 pieces. When I was in his manufacture, he was working on a new project and about to finish the first of 10 limited edition Titanium cased new watches. Unfortunately, he was not yet able to show me the ready timepiece. But he wanted to finish it that very day.

Considering that he employs 20 people and his annual output is only 38 watches, you can imagine how long it takes to make one watch: yes, approximately half a year. And that is due to the fact that he makes watches the „old“ way, the manual way, with highly skilled artisans.

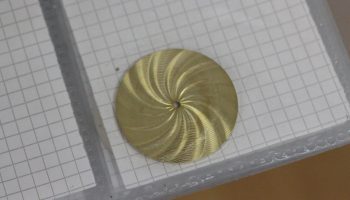

Not many watchmanufacturers nowadays really make a true guilloche dial just because it looks like it. They stamp it with modern machinery which takes a minute if at all to make. In Kari’s workshop, a guilloche dial takes about 2 days to make in average, depending on how many different patterns need to be engraved (engine turned as the correct notion would be).

Kari’s workshop is located in the beautiful Swiss Vallee de Travers, it is a beautiful gated mansion from old times where his 20 „artists“ as I would call them make some of the most amazing watches you will find.

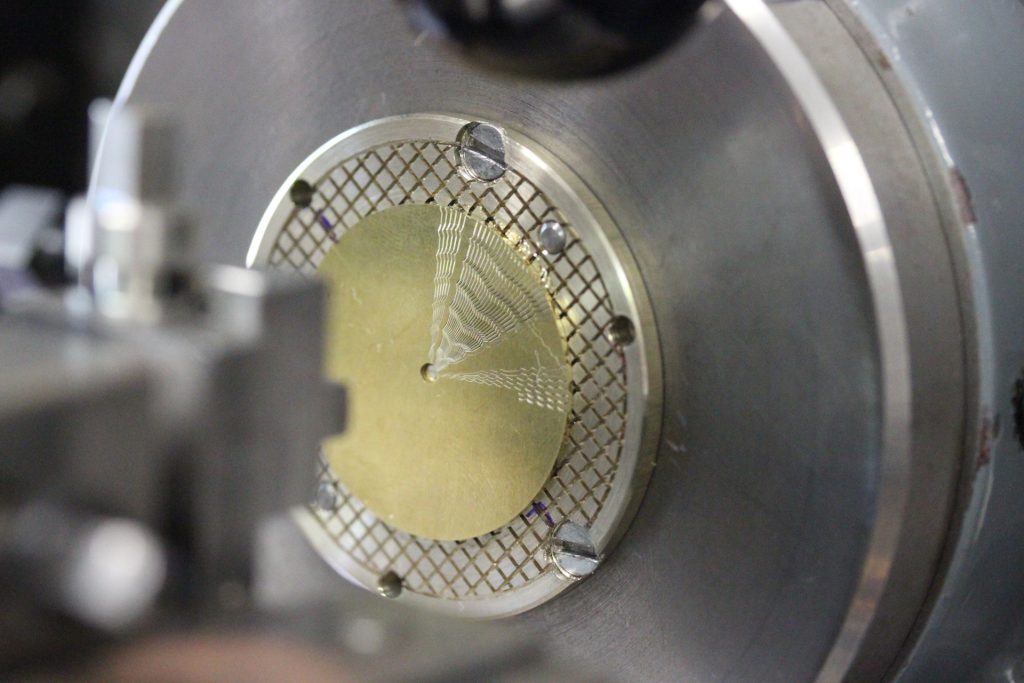

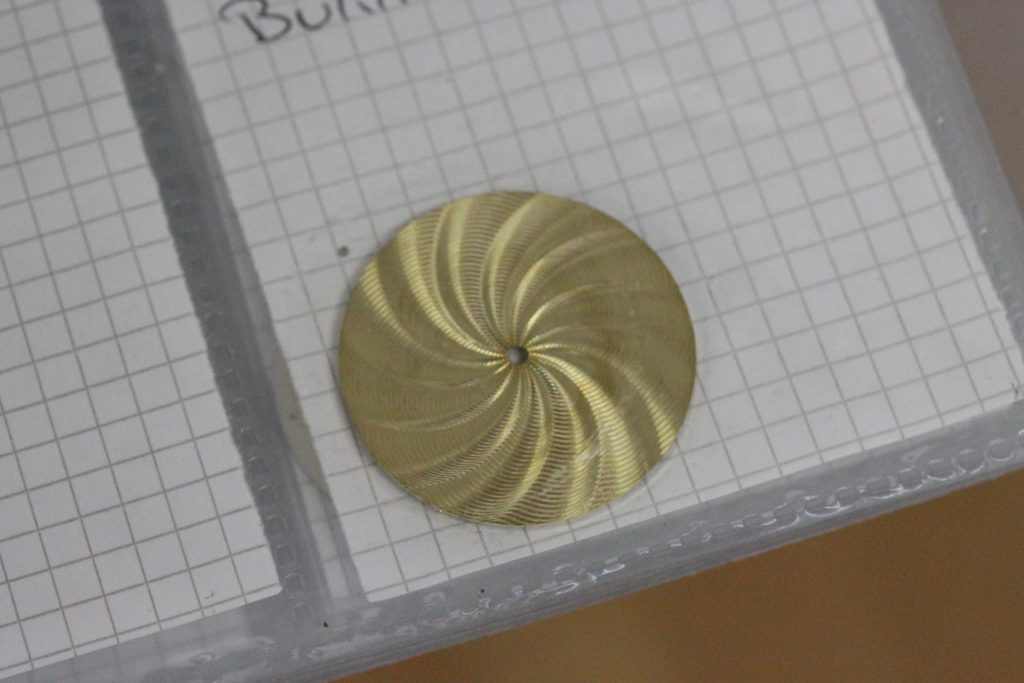

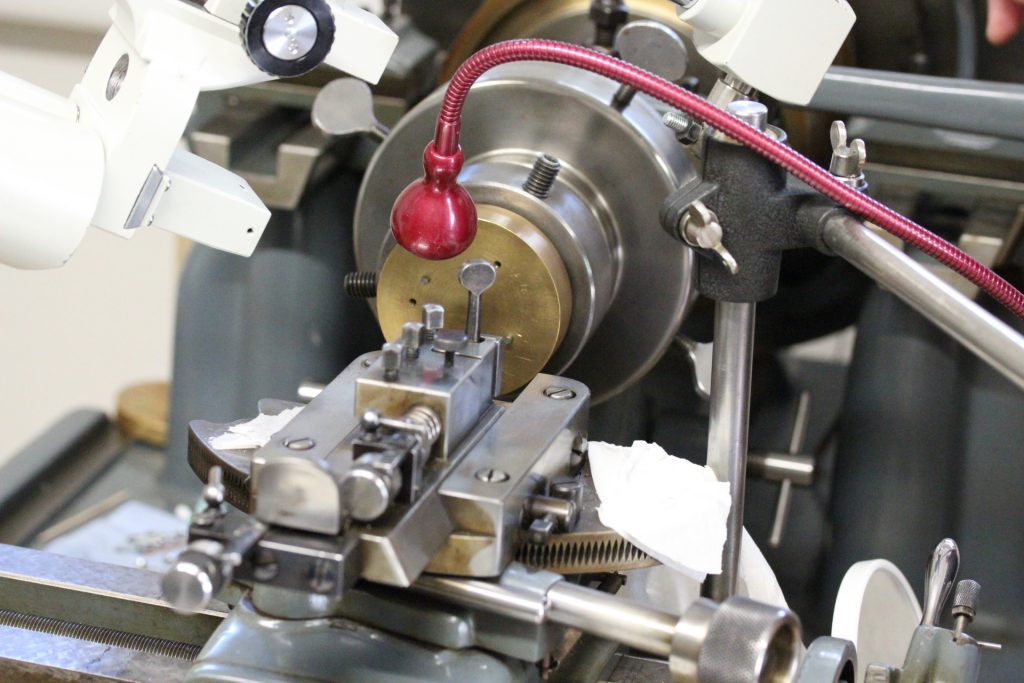

Kari is using old machinery which comes from the 1940s and 1950s to engine turn his dials. I was out of luck to be able to film how the engine turning is done as the two guillocheures had already left work. A typical Friday afternoon in Switzerland. However, I can show you the machines and some samples of the guilloche work.

You can see how the guilloche pattern is already „engraved“. The way the guilloche machine works is it is turned by hand (I guess that is the reason why they call it engine turning), and the cam bounces off a pattern which then is engraved on the dial.

Kari has a whole book filled with samples of possible guilloche patterns. This is just one picture of one example.

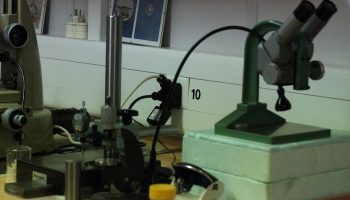

The guillocheur can watch through a microscope how precise his work is while performing.

These tools below are testing tools to check if the parts made are matching the required precision.

Kari is currently working on a GMT with a Titanium case, the case was featherlight and highly polished to look like steel. When I left his workshop, he returned to this watch as he wanted to finish it today. He is adding an enamel dial to the watch which I should have shot, but I only got to see the small seconds dial of it.

As it takes so long to create one watch (about half a year in true time), Kari has absolutely no stock. He makes watches and usually has sold them before they are even finished. Quite a privileged position. Kari also told me that he stopped making parts or anything for other watchmanufacturers, while in the early days he supplied a lot to others, he now fully works for his own watches. And it takes all his effort to create his masterpieces as well as the skilled talents of his watchmakers and artisans.

In addition, Kari has a new watchproject. He is creating a watch where the hands indicate time as we are used to, but the minute is indicated by a turning dial. A different approach, and I will share pictures as soon as he finishes this timepiece and before he delivers it. It is a watch that will go to an auction in the United States.

The movements are just as amazing and beautiful as the dials.

The movements are just as amazing and beautiful as the dials.

Kari Voutilainen’s cases have not only a unique distinction in the design of the lugs, but he also tries to keep his cases timeless. He uses round and not edged cases which will later on make it easier to be polished and it will be harder to recognize that they were polished. Overall, everything that Kari does with his watches is geared towards longevity, timeless design, uniqueness and an incredible perfection made by hand.

I am thankful for this experience and that Kari spent 3.5 hours with me talking watches, the industry, and other topics where we were very much on the same page. He showed me in depth his workshop, I met his coworkers who are making such wonderful timepieces. The time involved to make them is incredible and hard to understand when you have never seen a workshop like this. Setup for a guilloche machine takes about 4 hours alone. Then the true work starts. Skills like that cannot be studied or learning in school. They can only be acquired by learning by doing.

Look alone at the hands on this timepiece. These hands are fully made by hand. One hand consists of 3 pieces as far as I remember.

Look alone at the hands on this timepiece. These hands are fully made by hand. One hand consists of 3 pieces as far as I remember.

While most people are aware of famous brandnames, this is where true watchmaking is taking place. This is what you cannot see at your local jeweler. It is distinction and perfection made in smallest numbers as it is limited by the time involved to make one watch.

While most people are aware of famous brandnames, this is where true watchmaking is taking place. This is what you cannot see at your local jeweler. It is distinction and perfection made in smallest numbers as it is limited by the time involved to make one watch.

I am sure this will not be my last visit, and I am looking forward to see what Kari is making next.